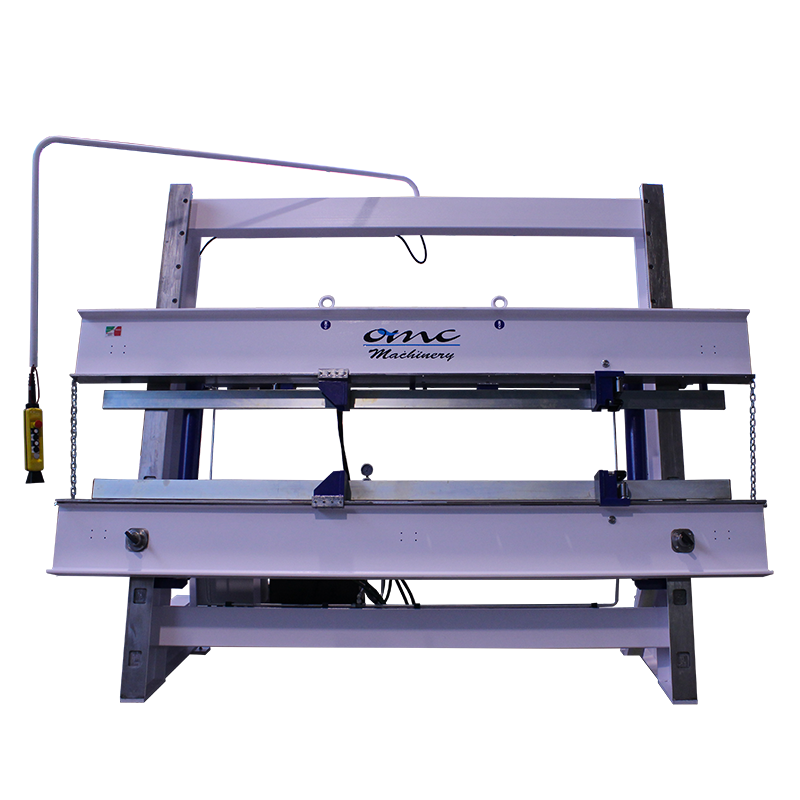

Frame presses

SBU frame presses

Applications

- Gluing of standard and pre-finished window frames;

- Gluing of door frames.

Final products

- Window frames;

- Door frames;

- Other types of frames (including trapezoidal, triangular frames, etc.).

Accessories/Options

The frame presses / clamps can be equipped with the following accessories

- Bar for shutters with fixed-pitch pins, non retractable;

- Bar for shutters with fixed-pitch pins, retractable with pneumatic system;

- Work surface covered with PVC;

- Pedal board for working “step by step”, for vertical cylinders only;

- Pneumatic preassembling devices (to lock the wooden frame and allow for manual assembling on the press);

- Additional horizontal beam with hydraulic cylinder;

- Hydraulic system for low pressures;

- Magnetic heads for pre-finished workpieces;

- Tilting heads for trapezoidal frames.

PFP

PFP

PFP

PFP

PFP

PFP

PFP

SBUm, SBUa and SBU r.a.

Applications

- Gluing of standard and pre-finished window frames;

- Gluing of door frames.

Models

- SBUm:

Manual mode with push-button panel;

- SBUa:

Automatic mode with “Touch screen” digital panel;

- SBU r.a.:

Automatic search mode: the structure that holds the workpieces is equipped with special sensors that can detect the size of the vertical and horizontal parts of the workpieces;

Dimensions

- 30/17: 3000×1700 mm;

- 30/20: 3000×2000 mm;

- 35/20: 3500×2000 mm;

- 35/25: 3500×2500 mm.

Standard equipment

- No. 2 vertical pistons;

- No. 2 horizontal pistons;

- No. 2 positionable counter brackets(fixed squares);

- No. 2 hydraulic piston heads(thrust “squares”);

- Lower beam adjustable in 3 positions;

- Push button panel (SBUm model);

- “Touch screen” digital panel (SBUa model).

PFP

PFP

PFP

PFP

PFP

SBU CNC

Applications:

- Gluing of standard and pre-finished window frames;

- Gluing of door frames.

Standard sizes

30/17: 3000×1700 mm;

30/20: 3000×2000 mm;

35/20: 3500×2000 mm;

35/25: 3500×2500 mm.

Standard equipment

- No. 2 vertical pistons;

- No. 2 horizontal pistons;

- No. 2 posizionable counter brackets (fixed squares);

- No. 2 hydraulic piston heads (thrust “squares”);

- No. 2 cylinders to lift/lower the lower horizontal beam;

- Workpiece pre-assembling devices;

- Electronic linear transducers;

- “Touch screen” digital panel.