Edge and face gluing presses

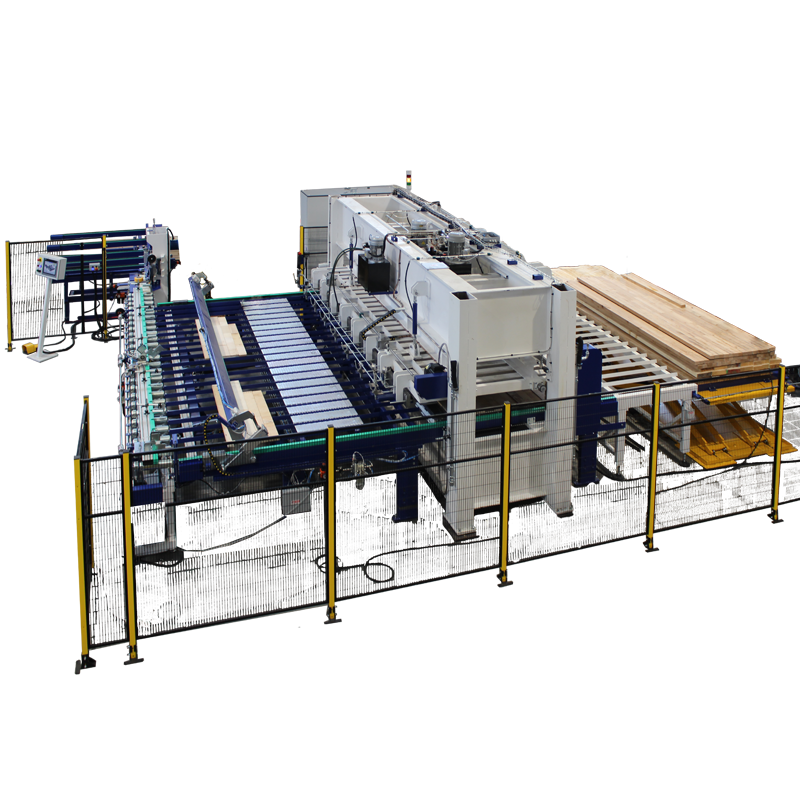

Automatic edge/face gluing pressing lines

PLS CA Model

Application

Production of edge glued panels (blockboards). The press is equipped with a back clamp to allow the production of panels larger than the pressing area.

Loading

Automatic loading onto motorized “comb” loading system.

Useful dimensions and hydraulic thrust

- 25/13: 2500×1300 mm, 1.5 – 5 Kg/cm2;

- 30/13: 3000×1300 mm, 1.5 – 5 Kg/cm2;

- 35/13: 3500×1300 mm, 1.5 – 5 Kg/cm2.

Standard equipment

- Horizontal hydraulic cylinders;

- Back clamp.

Optionals / Accessories

The PLS/CA press can be equipped with the following accessories / optionals:

- Loading system with motorized chains before the glue spreader;

- Automatic glue spreader with fixed or variable working width;

- Automatic single or multi-track feeder with stops to block the laths/batten run;

- High frequency generator;

- Automatic unloading system with lifting platform or other palletizing devices.

PFP

PFP

PFP

PFP

PFP

PLs-TL CA Model

PFP

PFP

PFP

Application: production of laminated beams

Loading/unloading systems:

- Automatic loading on conveyor belt activated by foot switch;

- Unloading on idle or motorized roller table.

Useful dimensions and hydraulic thrust

- 25/13: 2500×1300 mm, 10 Kg/cm2;

- 30/13: 3000×1300 mm, 10 Kg/cm2;

- 35/13: 3500×1300 mm, 10 Kg/cm2;

- 45/13: 4500×1300 mm, 10 Kg/cm2;

- 55/13: 5300×1300 mm, 10 Kg/cm2.

Standard equipment

- Structure made of thick oxy-cut steel sheets;

- Horizontal hydraulic cylinders;

- Fixed stop bar to counter the hydraulic thrust of the horizontal cylinders;

- Motorized belt system inside the press to receive and unload the workpieces;

- “Touch screen” digital control panel + PLC;

- Heating system with water or diathermic oil.

Optionals / Accessories

- Automatic loading system (belt);

- Automatic glue spreader;

- Automatic lay up system: The slats/lamella coming from the glue spreader is stopped and rotated 90° by a tilting device to form a pre-assembled lamella group. Each time the operator adds one lamella, the pre-assembled group moves down for the thickness of one lamella, to make room for the next one, until the entire composition is completed; the pre-assembled group of slats is then placed on the motorized roller conveyor to get into the press.

- High Frequency generator;

- Multilayer platen for High Frequency;

- Motorized unloading system with transfer device.