SPTL Model

Applications

- Gluing of wooden beams;

- Production of laminated (face glued) beams.

Final products

- Glued beams;

- laminated beams.

Accessories/Optionals

The clamps can be equipped with the following accessories:

- Counterweights for lower supports;

- Additional vertical upright with cylinder;

- Pneumatic front pressers;

- Control panel with multiple levers to divide the work area into multiple independent areas.

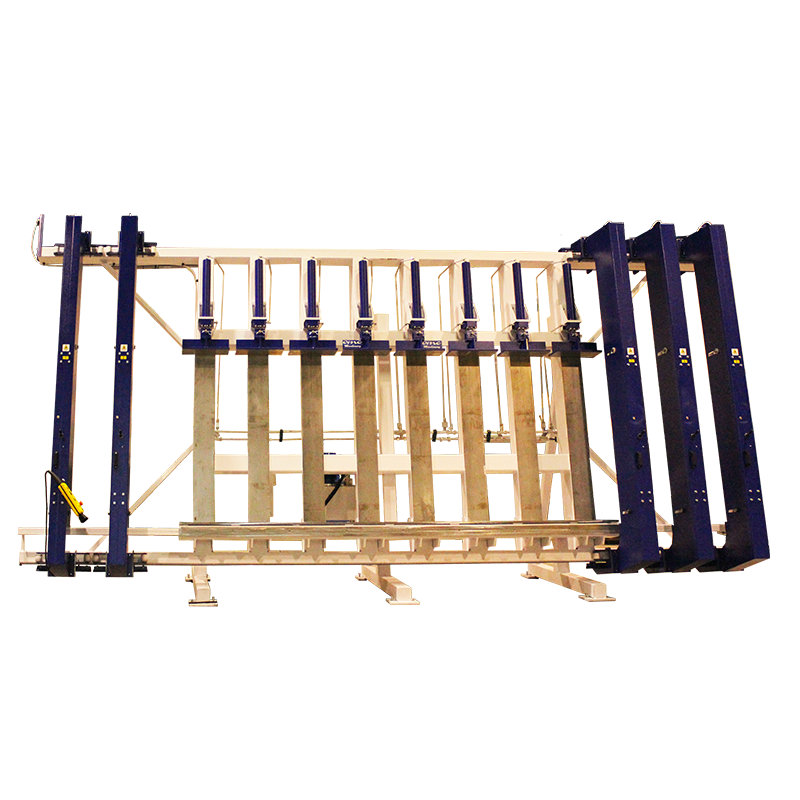

SPTL “base” model

Face gluing press for the production of window/door frames and laminated/lamellar beams.

The upright beams are equipped with pistons for vertical pressing.

This model is also equipped with manually positionable upright beams fitted with horizontal pneumatic pressers to lock the workpieces;

The hydraulic unit is controlled by a manual lever distributor; each cylinder is equipped with a manual exclusion valve.

Useful dimensions

- 3000×1300 mm, maximum beam thickness 150 mm;

- 4000×1300 mm, maximum beam thickness 150 mm;

- 5000×1300 mm, maximum beam thickness 150 mm;

- 6000×1300 mm, maximum beam thickness 150 mm.

Standard equipment

- 2 vertical pistons each length meter;

- hydraulic thrust of each cylinder: kg 2,500;

- Horizontal pressers.

SPTL Automatic

Face gluing press for the production of window/door frames and laminated/lamellar beams.The upright beams are equipped with pistons for vertical pressing.

This model is also equipped with manually positionable upright beams fitted with horizontal pneumatic pressers to lock the workpieces;

The SPTL Automatic model is equipped with an electric control keypad.

Pressure recovery device is included.

Standard equipment

- 2 vertical pistons each meter;

- Pneumatic vertical bars.

Useful dimensions

- 3000×1000 mm, maximum beam thickness 150 mm, 20 tons, 3 pneumatic vertical bars;

- 3000×1500 mm, maximum beam thickness 150 mm, 20 tons, 3 pneumatic vertical bars;

- 4000×1000 mm, maximum beam thickness 150 mm, 40 tons, 4 pneumatic vertical bars;

- 4000×1500 mm, maximum beam thickness 150 mm, 40 tons, 4 pneumatic vertical bars;

- 6000×1000 mm, maximum beam thickness 150 mm, 55 tons, 7 pneumatic vertical bars;

- 6000×1500 mm, maximum beam thickness 150 mm, 55 tons, 7 pneumatic vertical bars counter-batten;

- 9000×1000 mm, maximum beam thickness 150 mm, 80 tons, 10 pneumatic vertical bars;

- 9000×1500 mm, maximum beam thickness 150 mm, 80 tons, 10 pneumatic vertical bars;

- 3000×1000 mm, maximum beam thickness 200 mm, 60 tons, 3 pneumatic vertical bars;

- 3000×1500 mm, maximum beam thickness 200 mm, 60 tons, 3 pneumatic vertical bars;

- 4000×1000 mm, maximum beam thickness 200 mm, 80 tons, 4 pneumatic vertical bars;

- 4000×1500 mm, maximum beam thickness 200 mm, 80 tons, 4 pneumatic vertical bars contrast;

- 4500×1000 mm, maximum beam thickness 200 mm, 95 tons, 4 pneumatic vertical bars;

- 6000×1000 mm, maximum beam thickness 200 mm, 115 tons, 7 pneumatic vertical bars;

- 6000×1500 mm, maximum beam thickness 200 mm, 115 tons, 7 pneumatic vertical bars;

- 9000×1000 mm, maximum beam thickness 200 mm, 190 tons, 10 pneumatic vertical bars;

- 9000×1500 mm, maximum beam thickness 200 mm, 190 tons, 10 pneumatic vertical bars.

PFP

PFP

PFP