Cold presses for woodworking

PFP/PFPs presses

The PFP model has been specifically designed for pressing piles of panels, sandwich panels and doors.

PFP model

Loading side: short side.

Standard dimensions

- 2500×1300 mm;

- 3000×1300 mm;

- 3500×1300 mm.

Standard equipment

- Upper downstroke platen covered with a thick milled sheet metal;

- The pressing platen can be divided into 2/3 parts;

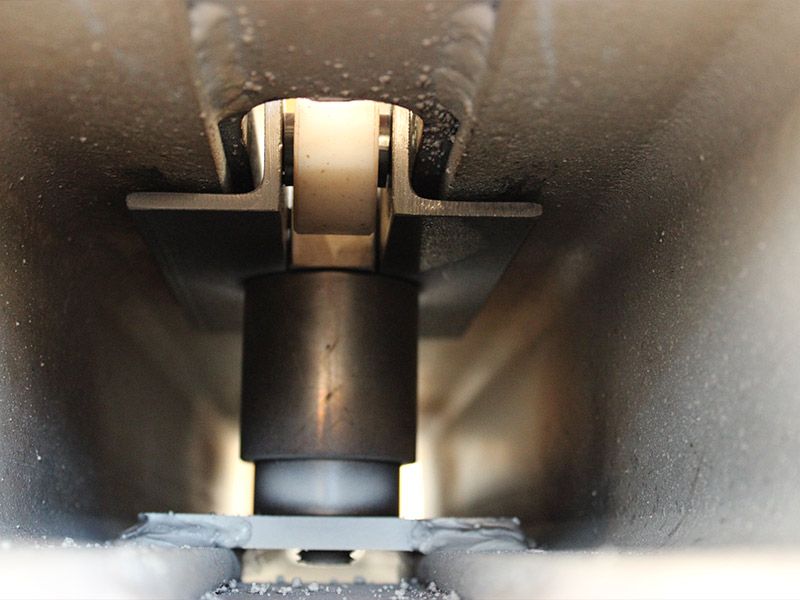

- Retractable wheels are installed on the lower fixed platen, to facilitate the loading and unloading operations;

- Standard control panel with pressure gauge;

- Automatic pressure recovery;

- Automatic opening via timer.

CE Compliance

The presses produced by OMC comply with the EC Machinery Directive 2006/42/EC.

Options / accessories

- Stroke 0-1000 mm;

- Motorized roller tables for loading / unloading;

- Motorized chain system inside the press for loading / unloading operations;

- Digital “touch screen” panel;

- Simultaneous closing of the platens.

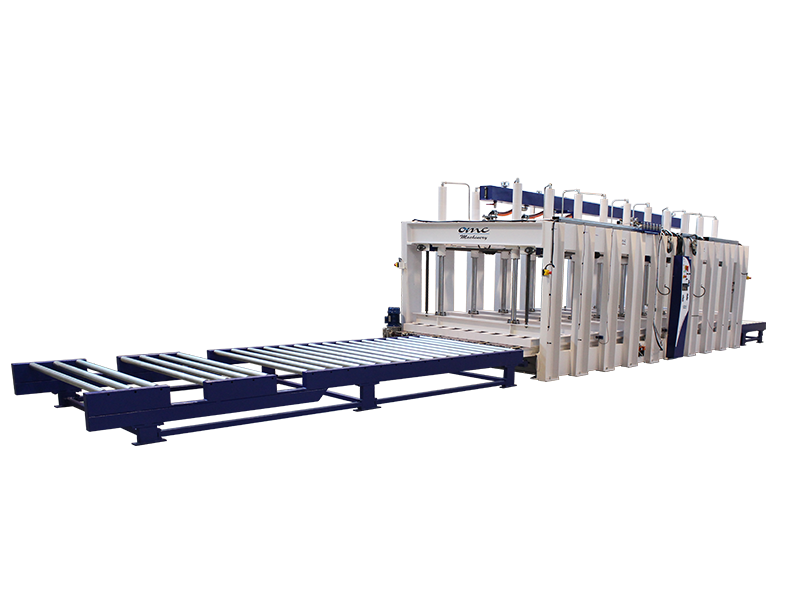

PFPs model

Loading side: long side.

Standard dimensions

- 2500×1300 mm;

- 3000×1300 mm;

- 3500×1300 mm.

Standard equipment

- Upper downstroke platen covered with a thick milled sheet metal;

- The pressing platen can be divided into 2/3 parts;

- Retractable wheels are installed on the lower fixed platen, to facilitate the loading and unloading operations;

- Standard control panel with pressure gauge;

- Automatic pressure recovery system;

- Automatic opening via timer;

Compliance

The presses produced by OMC comply with the EC Machinery Directive 2006/42/EC.

Options / Accessories

- Extra stroke 650 mm;

- Stroke 0-1000 mm;

- Motorized chain system inside the press for loading / unloading operations;

- Motorized loading / unloading table;

- Loading / unloading table with idle rollers;

- Digital “touch screen” panel;

- Simultaneous closing of the platens.