FLUID Series

The FLUID series can reach very high hydraulic pressures that allow to process processing particularly complex and delicate thermoformable materials.

Applications

- Coating of shaped surfaces with 3D thermoforming films (PVC, PPE, ABS etc.);

- Coating of shaped surfaces with veneer;

- Coating of shaped panels with aluminum (ALM Version).

Typical final products

- Various types of shaped panels;

- Doors, cabinet doors and flaps for bathrooms, kitchens etc;

- Aluminum coated doors.

Accessories/Options

The presses of the FLUID series can be equipped with various accessories:

- Vacuum pump with vacuum system (necessary for 3D thermoforming and Aluminum surfaces);

- Work table to be used with a single membrane (for the Fluid Double model);

- Adjustable temperature on each platen.

FLUID L and FLUID L CA

Applications:

This membrane press is suitable to coat workpieces with 3D thermoforming films and veneer on one side.

This model can reach a very high hydraulic pressure and is equipped with an oxy-cut structure to allow for the application of coatings on particularly complex surfaces.

Models and type of loading:

- “Fluid L” model: upstroke, manual loading;

- “Fluid L CA” model: upstroke, one work table, automatic loading;

- “Fluid L CA 2V” model: upstroke, two work tables, automatic loading onto the opposite side.

Usful dimensions and hydraulic thrust:

- 18/8: 1650×650 mm, 8 Kg/cm2;

- 24/8: 2250×650 mm, 8 Kg/cm2;

- 25/10: 2350×850 mm, 8 Kg/cm2.

Standard equipment:

- 1 rubber membrane;

- Heating system with diathermic oil.

FLUID M and FLUID M CA

Applications:

This membrane press is suitable to coat workpieces with 3D thermoforming films, glossy laminate (“High Gloss”) and veneer on one side.

This model can reach a very high hydraulic pressure and is equipped with an oxy-cut structure to allow for the application of coatings on particularly complex surfaces.

Models:

- Model “Fluid M”: upstroke, manual loading;

- Model “Fluid M CA”: upstroke, one work table, automatic loading;

- Model “Fluid M CA 2V”: upstroke, two work tables, automatic loading onto the opposite side.

Useful dimensions and hydraulic thrust:

- 18/8: 1650×650 mm, 16 Kg/cm2;

- 24/8: 2250×650 mm, 18 Kg/cm2;

- 25/10: 2350×850 mm, 18 Kg/cm2;

Standard equipment:

- 1 rubber membrane;

- Heating system with diathermic oil.

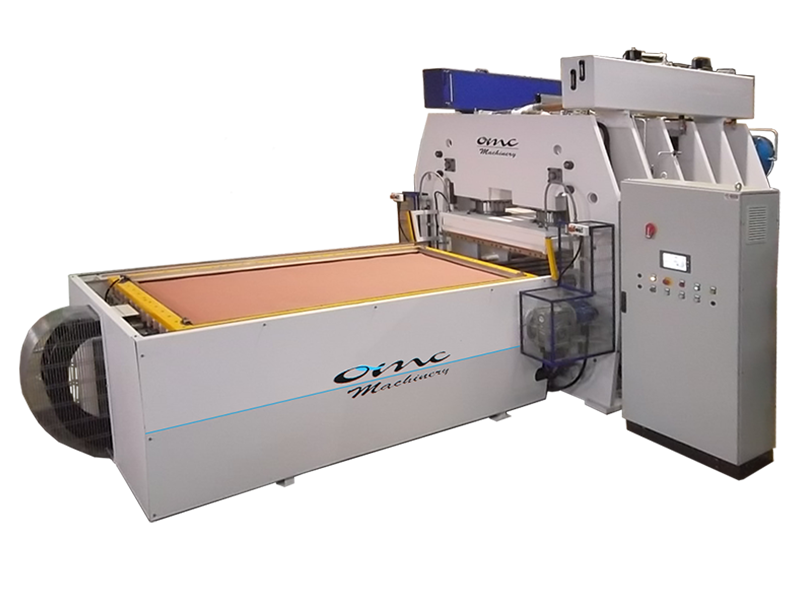

FLUID P and FLUID P CA

Applications:

This membrane press is suitable to coat workpieces with 3D thermoforming films, glossy laminate (“High Gloss”), ALUMINIUM (ALM version only) and veneer on one side.

This model can reach a very high hydraulic pressure and is equipped with an oxy-cut structure to allow for the application of coatings on particularly complex surfaces.

Models:

- Model “Fluid P”: upstroke, manual loading;

- Model “Fluid P CA”: upstroke, one work table, automatic loading;

- Model “Fluid P CA 2V”: upstroke, two work table, automatic loading onto the opposite side.

Useful dimensions and hydraulic thrust:

- 18/8: 1650×650 mm, 16 Kg/cm2;

- 24/8: 2250×650 mm, 18 Kg/cm2;

- 25/10: 2350×850 mm, 18 Kg/cm2;

- 25/10: 2350×850 mm, 25 Kg/cm2 (ALM version).

Standard equipment:

- 1 rubber membrane.

- Heating system with diathermic oil.

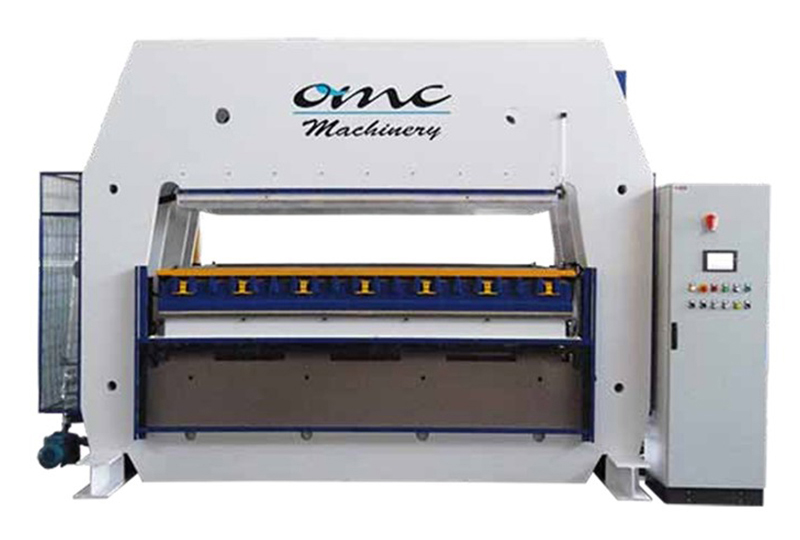

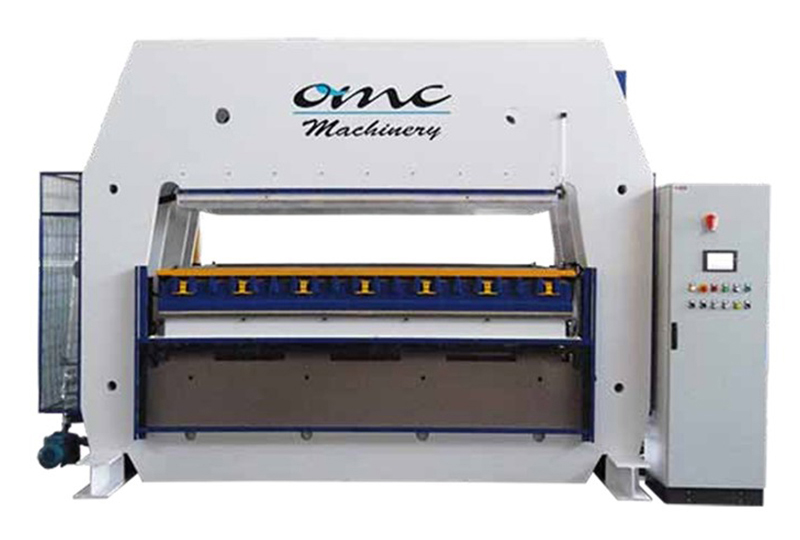

FLUID DOUBLE

Applications:

This membrane press is suitable to coat workpieces with 3D thermoforming films, and veneer on TWO sides.

This model can reach a very high hydraulic pressure and is equipped with an oxy-cut structure to allow for the application of coatings on particularly complex surfaces.

Models:

- “Fluid Double”: upstroke, manual loading;

- “Fluid Double CA”: upstroke, one work table, automatic loading;

- “Fluid Double CA 2V”: upstroke, two work tables, automatic loading onto the opposite side.

Useful dimensions and thrust:

- 18/8: 1650×650 mm, 8 Kg/cm2;

- 18/8: 1650×650 mm, 16 Kg/cm2;

- 24/8: 2250×650 mm, 8 Kg/cm2;

- 24/8: 2250×650 mm, 18 Kg/cm2;

- 25/10: 2350×850 mm, 18 Kg/cm2.

Standard equipment:

- 2 rubber membranes;

- Heating system with diathermic oil.