Edge and face gluing presses

Face gluing press

A “face gluing” press is designed to produce laminated timber by gluing slats/lamella with adhesive on the face of the workpiece; laminated beams are capable of providing high structural resistance, higher to that of solid wood.

Laminated timber is very stable and versatile and therefore particularly suitable for the construction industry; the work process of laminating also offers the opportunity to use multiple types of wood and therefore enhance the aesthetics of the product finishes.

Applications

- Production of window/door frames;

- Production of laminated beams for the construction industry.

Final products

- Window/door frames;

- laminated beams;

- Wide-span load-bearing beams;

- Trusses and roof structures.

PLs/TL

This press has been designed to produce laminated beams.

Models and loading system:

- PLs/TL-A (Maximum slat thickness 4 cm);

- PLs/TL-B (Maximum slat thickness 8 cm);

- PLs/TL-C (Maximum slat thickness 15 cm).

Manual loading on automatic loading system operated by pedal switch.

Unloading on idle roller table.

Useful dimensions and thrust

PLs/TL-A (Maximum slat thickness: 4 cm)

- 25/13: 2500×1300 mm, 10 Kg/cm2;

- 30/13: 3000×1300 mm, 10 Kg/cm2;

- 35/13: 3500×1300 mm, 10 Kg/cm2;

- 45/13: 4500×1300 mm, 10 Kg/cm2;

- 55/13: 5300×1300 mm, 10 Kg/cm2.

PLs/TL-B (Maximum slat thickness 8 cm)

- 25/13: 2500×1300 mm, 10 Kg/cm2;

- 30/13: 3000×1300 mm, 10 Kg/cm2;

- 35/13: 3500×1300 mm, 10 Kg/cm2;

- 45/13: 4500×1300 mm, 10 Kg/cm2;

- 55/13: 5300×1300 mm, 10 Kg/cm2.

PLs/TL-C (Maximum slat thickness 15 cm)

- 25/13: 2500×1300 mm, 10 Kg/cm2;

- 30/13: 3000×1300 mm, 10 Kg/cm2;

- 35/13: 3500×1300 mm, 10 Kg/cm2;

- 45/13: 4500×1300 mm, 10 Kg/cm2;

- 55/13: 5300×1300 mm, 10 Kg/cm2.

Standard equipment

- Structure made of oxy-cut steel sheets;

- Horizontal cylinders;

- Fixed stop bar to counter the thrust of the horizontal cylinders;

- Loading system with pusher;

- Unloading table with idle wheels;

- “Touch screen” digital panel + PLC;

- heating system with water/diathermic oil;

Accessories/Options

The PLS/TL presses can be equipped with the following accessories:

PLS CA model

- Automatic loading system (belt conveyor);

- Automatic glue spreader;

- Automatic composition system: the slats/lamellas /wood strips coming from the glue spreader are stopped and rotated 90° by a tilting device to form a pre-assembled group on a chain driven roller table . Each time a slat/lamella is added, the pre-assembled group goes down to make room for the next one, until the entire composition is completed.; the pre-assembled group of slats is then placed on the motorized roller conveyor to get into the press;

- High frequency generator;

- Platens fitted with plywood for high frequency;

- Motorized unloading system with transfer device.

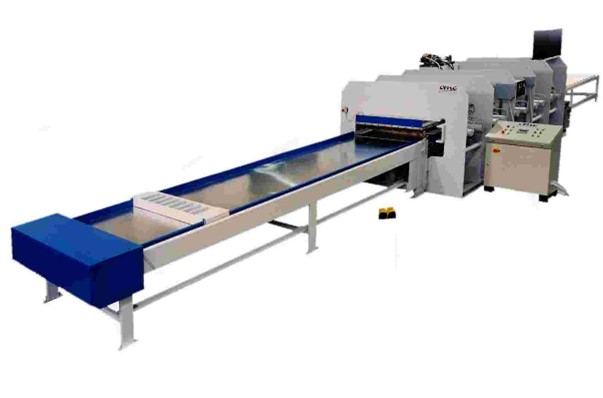

PLs/TL CA

Automatic pressing line to produce laminated beams.

Loading/unloading systems:

- Automatic loading on conveyor belt activated by foot switch;

- Unloading on idle or motorized roller table.

Useful dimensions and hydraulic thrust

- 25/13: 2500×1300 mm, 10 Kg/cm2;

- 30/13: 3000×1300 mm, 10 Kg/cm2;

- 35/13: 3500×1300 mm, 10 Kg/cm2;

- 45/13: 4500×1300 mm, 10 Kg/cm2;

- 55/13: 5300×1300 mm, 10 Kg/cm2.

Standard equipment

- Structure made of oxy-cut steel sheets;

- Horizontal hydraulic cylinders;

- Fixed stop bar to counter the hydraulic thrust of the horizontal cylinders;

- Motorized belt system inside the press to receive and unload the workpieces;

- “Touch screen” digital control panel + PLC;

- heating system with water or diathermic oil.

Optionals / Accessories

- Automatic loading system (belt);

- Automatic glue spreader;

- Automatic lay up system: The slats/lamella coming from the glue spreader is stopped and rotated 90° by a tilting device to form a pre-assembled lamella group. Each time the operator adds one lamella, the pre-assembled group moves down for the thickness of one lamella, to make room for the next one, until the entire composition is completed; the pre-assembled group of slats is then placed on the motorized roller conveyor to get into the press;

- High Frequency generator;

- Multilayer platen for High Frequency;

- Motorized unloading system with transfer device.