About us

About us

Our company

OMC Machinery Srl designs and manufactures presses for processing wood, rubber, expanded materials, solid surfaces and innovative materials.

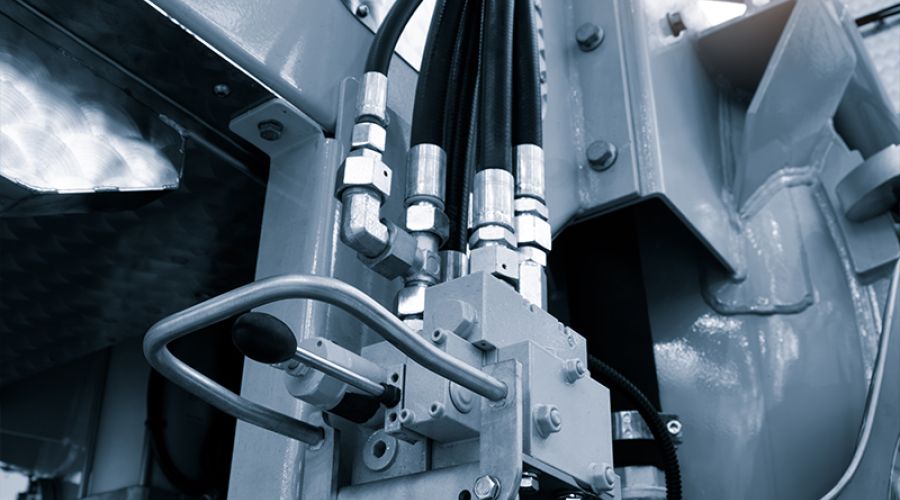

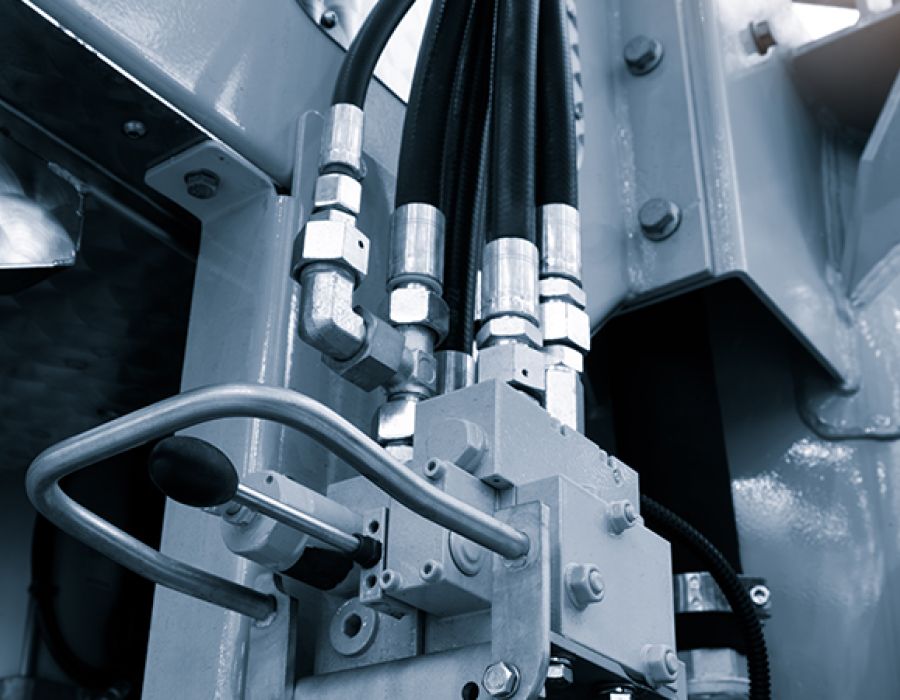

Thanks to our own 5 specialized departments (metal-work, mechanics, hydro-pneumatic, painting and finishing department), we are able to independently produce all press components.

Our in-house production capability allows us to guarantee 100% internal quality control on every mechanical-structural component.

As a result we are able not only to guarantee long time reliability, but also to easily customize our presses according to specific customer needs.

From the experience we have built up over the years, we have learned that, in order to design and manufacture the “Right Press”, it is essential to establish an in-depth dialogue with the customer: fully understanding customer’s needs to design the right press configuration is the first step towards success.

Our team

The goal of OMC Machinery srl is the continuous improvement of our technology in conjunction with the development of a network of partner throughout the world.

We are a group of passionate and highly qualified professionals, united by a passion for technology and innovation. Each member of our team brings with them a unique mix of skills and expertise, which allows us to tackle each project with creativity and accuracy.

Livio Colleoni

Working every day in both the production Department and the Design Office: this makes him a true Leader. He motivates and pushes the team to always give their best.

The true backbone of OMC Machinery.

tel. +39 035 841280

cel. +39 335 7449904

mail: info@omcpresse.it

Cristina Fratus

Cristina takes care of the administrative and accounting part: please contact her for any accounting related query.

tel +39 035 841280[Extension 1]

mail: amministrazione@omcpresse.it

Francesca Gambarini

Francesca takes care of purchasing goods and developing relationships with suppliers: she is always looking for the best materials and tools for our production.

tel +39 035 841280 [Extension 4]

mail: ufficioacquisti@omcpresse.it

Veronica Colleoni

Veronica is in charge of the Spare Parts Department: she receives enquiries, sends out quotations and is on top of the process from enquiry to shipment.

tel +39 035 841280 [Extension 4]

cel. +39 329 2190990

mail: ricambi@omcpresse.it

Marilena Colleoni

Marilena is in charge of the Production Department and interacts directly with customers.

tel +39 035 841280 [Extension 2]

cel. +39 345 2166341

mail: produzione@omcpresse.it

Andrea Pescatori

Andrea takes care of the commercial side, developing relationships with customers and opening new markets; he is in charge of quotations and promotional offers.

tel +39 035 841280 [Extension 0]

cel. +39 339 2188126

mail: commerciale@omcpresse.it

Matteo Grismondi

Matteo, thanks to his decades of experience, follows the commissioning, training and service.

He is always looking for innovative applications and is part of the research and development team in our technical office.

Cel +39 3357449903

tel +39 035 841280 [Extension 2]

mail: service@omcpresse.it

Nicola Quarenghi

Nicola is in charge of our Design Office: he is always looking for innovative technological solutions to use for the new projects.

tel +39 035 841280 [Extension 2]

mail: progettazione@omcpresse.it

A journey through the past: our history year-by-year

1983 | Subcontractor Workplace: home garage | |

1994 | New warehouse located in Bolgare |  |

2000 | Enlargment of the warehouse in Bolgare – production of the first 2 daylight presses |  |

2003 | First face gluing press wtih automatic loading system |  |

2013 | Further enlargment of the warehouse in Bolgare – production of the fist 2 daylight presses |  |

2014 | Launch of the first “T-shaped” press for rubber applications |  |

2016 | Launch of the first forming presses for composite materials, with rack&pinion or column stroke systems |  |

2017 | Expansion of the metal workshop |  |

2020 | Launch of the “SPTL” face gluing press with independent work stations and automatic loading |  |

2024 | Launch of the “CPB” Cabinet Press |  |

1989 | Fisrt warehouse located in Costa di Mezzate Manufacture of the first PL presses and frame presses | |

1994 | First XYLEXPO as exhibitor – presentation of the OMC Machinery range |  |

2002 | Production of the first automation systems |  |

2012 | First Fluid Press “Double” with 2 trays |  |

2013 | Launch of the new line of PLCC Automatic presses |  |

2015 | Launch of the new line of Vacuum presses for “Solid surface” applications |  |

2016 | Launch of edge and face gluing/pressing lines with automatic loading |  |

2018 | Manufacture of the new press models for foam materials |  |

2020 | Production of the new press for XLAM/GLULAM/CLT panels |  |

2024 | Launch of the 4+4 Multidaylight Press |  |

OMC Values

Our core values guide every aspect of our work. These principles allow us to maintain high standards of quality, innovation and customer service.

Here are the values that we aim to stand out for:

Excellence and Quality

Every product that leaves our factory is the result of a rigorous quality control process, to meet the highest standards in the industry.

Innovation and Sustainability

We use the latest technologies to improve the efficiency and quality of our production, ensuring that our products are state of the art.

Collaboration and Integrity

We operate with maximum transparency towards our customers and partners, as we think that relationships are based on trust and honesty.

Departments

Our company structure consists of 3 operating units divided into 5 specialized departments, which allow for 100% in-house production. Such organization allows us to guarantee high standards of quality, efficiency and flexibility in every step of the production process.