Pressing lines with PLA CA or PLCC presses

Pusher on lifting platform

The hydraulic lifting platform, manufactured by OMC, automatically rises to working level, so that the pneumatic pusher can push the top panel of the stack into the following station (e.g. brushing / gluing machine etc.).

The electro-pneumatic pusher, manufactured by OMC, can load panels of any thickness, down to a minimum of 10 mm, into the following station (brushing or gluing machine). The pusher is also equipped with a suction cup system to push forward workpieces with a thickness of less than 10 mm.

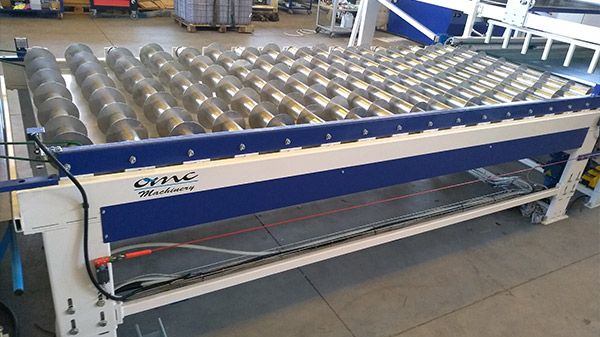

Disc conveyor

The disc conveyor, manufactured by OMC, receives the panels from the gluing machine (the conveyor can be equipped either with motorized or idle discs). The thin discs minimize the contact surface with the layer of glue of the panels.

The thin discs are used to have the smallest possible contact surface with the glue layer of the panels.

Standard equipment

- The structure is made of welded steel profiles, and it is adjustable in height to compensate for uneven floors; and the height is adjustable to compensate for possible uneven floors;

- The discs dip into the water inside a tank made of galvanized sheet: this allows for self-cleaning and avoids the need for daily washing;

- The discs are made of stainless steel to prevent the formation of glue encrustations.

Storage station for coating materials

Fixed station

A storage station with shelves can be installed on top of the disc conveyor to stock the coating materials (veneer, laminate etc.).

The operator can manually pick up the coating material to be placed under/on top of the panel on the loading belt of the next station;Motorized station

A motorized storage station with foot switch can be installed beside the loading belt: the operator activates the forward/backward movement of the shelves that move above the loading table towards the operator who can easily pick up the coating material and place it on the belt.

Loading table

The structure of the loading table is made of welded steel profiles, and the height is adjustable to compensate for possible uneven floors.

The PVC belt allows for easy cleaning from residues of two-component polyurethane glues.

The table is equipped with a system for adjusting the centering and tensioning of the belt.

The belt is activated by a foot switch.

The motorization of the belt is controlled by a variable speed motor with adjustable speed via inverter.

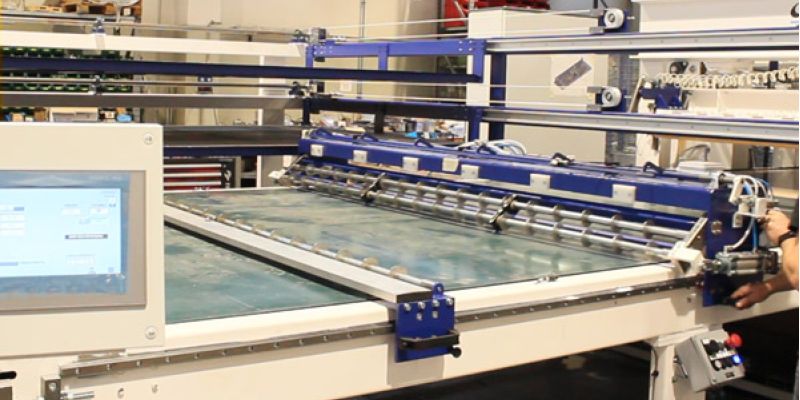

Positioner

The positioner takes the panel coming out of the gluing machine and places it with the right alignment on top of the coating material (veneer / laminate) previously placed by the operator on the loading belt.

- Automatic chain positioner:

The disc-holder bars emerge from under the loading table to take the panel coming out of the gluing machine and place it on the loading belt. Once the panel is over the loading table, the disc-holder bars reverse direction and return to their initial position, while the panel is stopped by a bar and is gently laid on the loading table; - Automatic positioner with sliding carriage:

A vice driven by pneumatic cylinders grabs the panel, takes it over the loading table and drops it gently on the loading belt; - Manual positioner with sliding carriage:

A vice driven by pneumatic cylinders locks the panel and the operator pushes the carriage along the loading table and lets the panel drop down gently on the loading belt.

Press models

- PLA CA

The structure is made of assembled and welded S275JR steel beams.

The press is equipped with a rotating belt system for the loading and unloading of the workpieces.

Specific pressure up to about 5 kg/cm2; - PLCC

Closed ring structure made of modular oxy-cut steel sheets with no welding.

The press is equipped with a rotating belt system for the loading and unloading of the workpieces.

Specific pressure greater than 5 kg/cm2.

PLA CA

PLCC

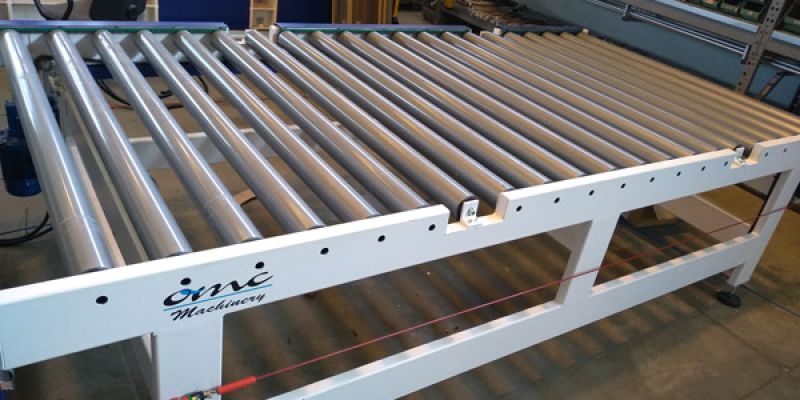

Unloading system

- Unloading table with idle wheels:

When the pressing cycle is finished, the panels are pushed out of the press by the rotation of the belt system onto the unloading table with idle wheels

The sliding of the panel on the idle wheels occurs by gravity.

The structure of the unloading table is made of welded steel profiles, and the height is adjustable to compensate for possible uneven floors; - Motorized roller table:

The panels automatically exit the press and are placed onto the motorized roller table at the end of the pressing cycle.

The motorized rollers can transfer the pressed panels to the next station.

The structure of the loading table is made of welded steel profiles, and the height is adjustable to compensate for possible uneven floors; - Automatic stacker:

The automatic stacker piles up the panels at the end of the line. The stacker belt system lays down the panel and then lifts up automatically to place the next panel on top of the pile.